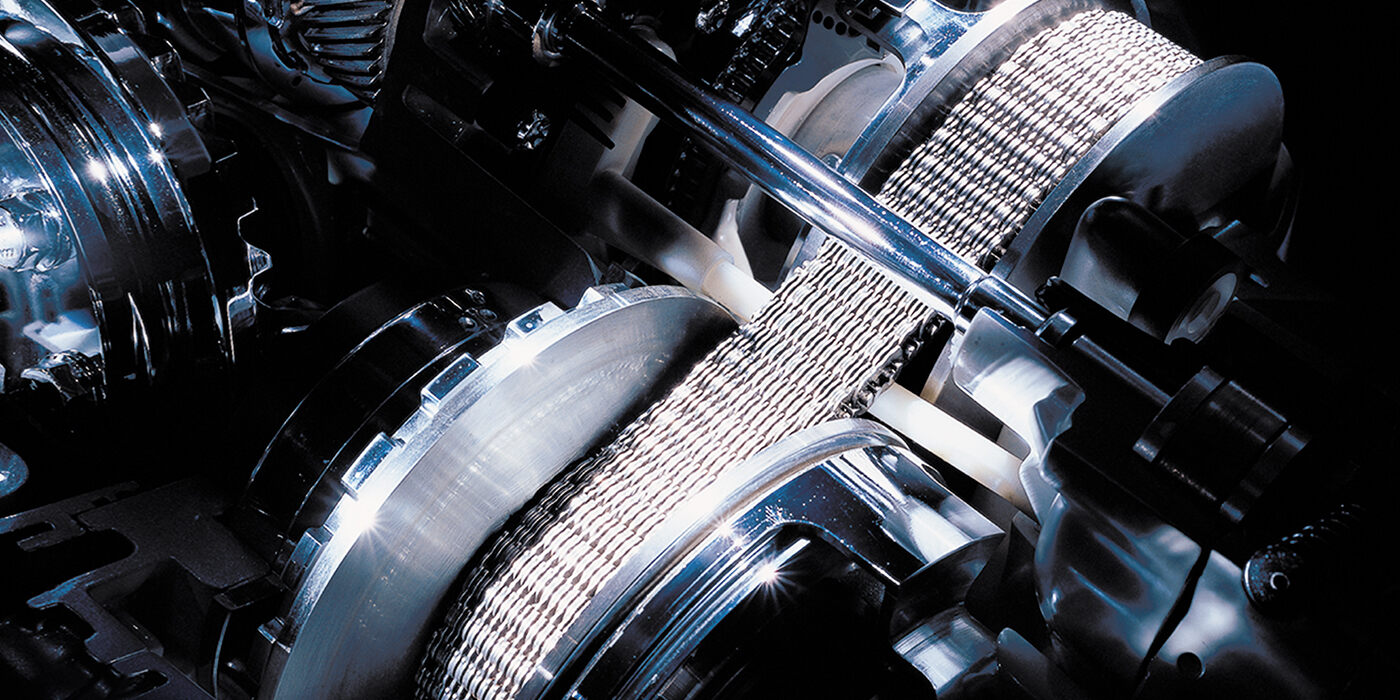

CVT transmission process is often known as single-pace, shiftless and Stepless transmission. The shiftless mother nature from the CVT supplies unparalleled overall flexibility that maintains a relentless angular velocity regardless of output speed.

A belt-pushed layout offers about 88% efficiency,[3] which, though decreased than that of a handbook transmission, can be offset by enabling the engine to run at its most economical RPM whatever the car's velocity.

CVTs excel in boosting fuel performance and providing a smoother driving working experience by optimizing engine effectiveness and providing seamless acceleration without having gear shifts.

This differs from other sorts of mechanical transmissions which provide a fixed amount of gear ratios and also have hard shifts amongst each. In essence, it’s about understanding how cvt performs.

Fuel Efficiency: Usually far more gas-effective than standard transmissions as it can maintain ideal motor speeds.

CVT features a all-natural disadvantage since many of them are programmed in a way that makes customers Believe they’re broken or Operating improperly.

After you phase to the gas pedal of an automobile that has a continuously variable transmission, you discover the real difference straight away. The engine revs up toward the rpms at which it generates the most energy, then it stays there. Though the car does not react right away. Then, a second later, the transmission kicks in, accelerating the car slowly, steadily and with none shifts.

When electricity is much more important than financial state, the ratio with the CVT could be changed to enable the engine anonymous to show with the RPM at which it produces the greatest ability.

Greater fat. Due to superior oil pressure at which a hydrostatic CVT operates, the pump and motor(s) are under considerable mechanical tension, especially when highest electrical power and loading is currently being utilized.

These differ from standard CVTs in that they're powered by An electrical motor Together with the engine, often applying planetary gears to mix their outputs as opposed to a belt used in traditional CVTs. A noteworthy illustration would be the Toyota Hybrid Synergy Generate.

Between the discs are rollers, which change the ratio and transfer ability from just one aspect to another. When the rollers' axes are perpendicular into the axis with the discs, the successful diameter is the same with the enter discs as well as the output discs, resulting in a one:1 drive ratio. For other ratios, the rollers are rotated together the surfaces on the discs so that they are in connection with the discs at details with diverse diameters, leading to a drive ratio of something other than one:1.[14]

In this sort of transmission, the rotational movement of your motor operates a hydrostatic pump around the driving facet. The pump converts rotational motion into fluid circulation. Then, which has a hydrostatic motor Situated on the pushed side, the fluid move is converted back again into rotational movement.

It very same as fixed enter pulley but in contrast to preset input shaft this shaft is put on the left-hand side over the output shaft.

If performance isn’t your prime priority, you primarily use your car all around town and you just don’t need a guide, then a CVT computerized might take advantage of sense. Driving lovers and people right after the final word in refinement are likely to choose a unique type of automated gearbox.

Comments on “Details, Fiction and gearbox cvt”